We make energy work for you!

We provide complete solutions for commercial & industrial gas systems, combustion and thermal energy applications, and process engineering.

From design to installation and after-sales support, we combine technical know-how, innovation and quality to deliver reliable, tailor-made solutions.

Our approach combines scientific principles — thermodynamics, fluid dynamics, and heat transfer — with practical applications to:

- Optimize energy use

- Reduce environmental impact

- Enhance operational efficiency

Engineering

End-to-end project handling capabilities, from design to implementation

The Team

A team of 90+ engineers, CAD drafters, and fabricators enabling end-to-end execution from design to commissioning.

CAD Systems & Calculation Tools

In-house 2D/3D CAD tools and proprietary calculation software for process, energy, and fluid analysis.

Project Execution & Site Management

ISO 45001 certified for occupational health and safety. ASNT Level II certified supervisors ensure safe execution with adaptable on-site solutions.

After-Sales Support

Direct collaboration with the engineering team ensures continuity and expert support.

Fabrication

Fabrication shop approved by the Petroleum & Explosives Safety Organization under SMPV Rules 2016.

Welding Facilities

Advanced welding: Equipped with robotic, orbital, and laser technologies.

Processes: SMAW (ARC), GMAW (MIG), GTAW (TIG).

Materials: Mild Steel, Stainless Steel, Aluminium.

Compliance: All procedures and welders qualified as per ASME Section IX.Equipment & Infrastructure

CNC lathes, multi-functional punching and shearing machines, magnetic drilling machines, sheet rolling, and specialized tube coiling machines for custom spiral heat exchangers.

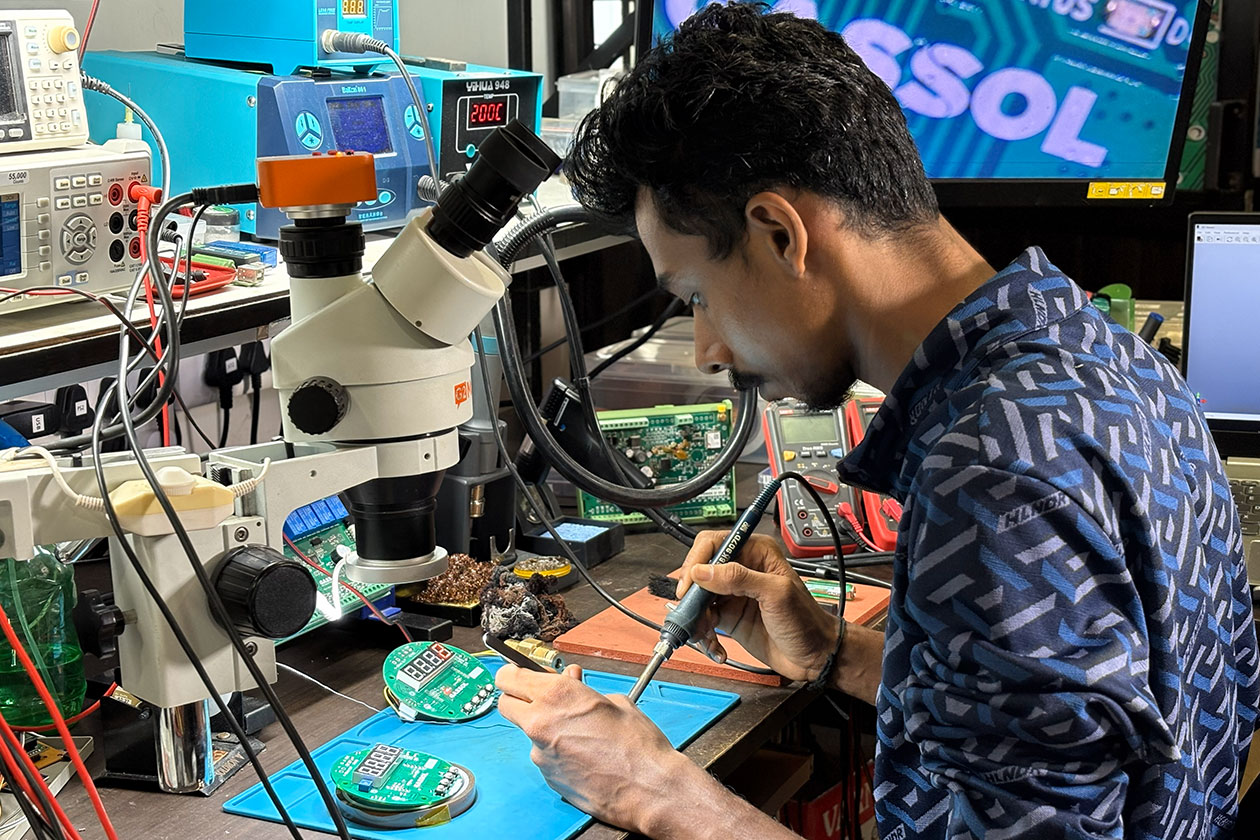

Instrumentation

Our lab features multi-function process calibrators capable of simulating voltage, current, resistance, frequency, thermocouples, and RTDs.

Design & Integration

Electrical & Instrumentation (E&I) team handles component selection and seamless integration.

Control Systems

In-house custom circuit boards.

PLC programming for manufacturing and automation needs.

Cloud-enabled panels for remote access, data logging, and SMS/Email alerts.Testing & Maintenance

Qualified technicians conduct in-house electrical testing to ensure control system accuracy.

Quality and Testing

We are actively pursuing NABL accreditation for pressure and temperature calibration facilities.

Quality Management

All processes follow ISO-certified quality management systems.

Testing Infrastructure

Pressure calibration up to 350 bar.

Temperature calibration up to 650°C.

Gas leak detection and relief valve testing.Certification Compliance

Fully documented, traceable, and compliant with relevant standards.