Liquified Petroleum Gas continued to gain popularity as a fuel source because of abundant supplies, low cost and an environmentally friendly profile compared to other fuels. Besides its ease of use, these benefits have made LPG a desirable fuel for industrial thermal processes.

Implementing LPG fuel for any industrial applications requires a technical understanding. LPG system design mainly takes into consideration:

a) Nature of vaporisation which is inherent to LPG fuel usage and vaporisation of related variables, including LPG boil-off rate and ambient storage temperature.

b) Size and fill level of the LPG cylinder being used.

c) Cylinder pressure.

d) Fuel consumption rate of supported equipment, potential safety issues, failure rates and necessary redundancy.

Natural Vaporization.

At standard pressure and temperature, LPG exists as a gaseous fuel. However, for its efficient storage and handling, the Gaseous state is liquefied under modest pressure to produce LPG (liquefied petroleum gas), a form that is 250 times reduced from its natural state. In this form, LPG can be easily and economically transported and stored as a liquid under pressure in cylinders.

For your equipment (boiler, process burner, heater) to consume LPG, the liquid must first be returned to its gaseous state, through a process referred to as vaporisation.

The good news is, depending on the propane and butane mixture with a boiling point is between -42 °C to -4 °C, LPG is naturally vaporised at ambient temperatures. Merely releasing LPG from its pressurised storage container is often enough to allow natural vaporisation to occur and produce a flow of LPG vapour typically sufficient for residential and light commercial applications.

Why Use a Vaporiser?

For the continuous operation of your application, the amount of gas your equipment draws from your cylinder must be matched by the rate of vaporisation. However, natural vaporisation performance has its limits, as it is a function of ambient temperature, cylinder size and LPG level in the cylinder.

A higher ambient temperature will cause a faster vaporisation rate and a higher vapour pressure. Like vaporisation, a fuller cylinder (with greater “wetted” surface area) will offer a greater vaporising capacity.

In lower ambient temperatures or a smaller or less full cylinder, vapour pressure and capacity may be lacking. For example, when the LPG liquid’s temperature falls below its boiling point, vaporisation may slow down or even stop altogether. As LPG is released from the cylinder, the cylinder’s pressure will fall accordingly. As the pressure drops, the remaining liquid within the cylinder cools.

If the vessel’s liquid temperature falls below the dew point of ambient air, frost will appear on the lower part of the cylinder and extend up towards the liquid level. If your cylinder is routinely icing up, it’s a good indicator your cylinder is not enough for the vaporisation load being placed on it.

For heavier vaporisation industrial applications which call for larger, more demanding LPG consuming equipment, natural vaporisation is often insufficient. It cannot provide vaporisation of vapour demanded by these more robust applications.

If your equipment is not getting the vapour pressure it needs, it may deliver less heat than your application requires, or even more damaging shut down your operation entirely.

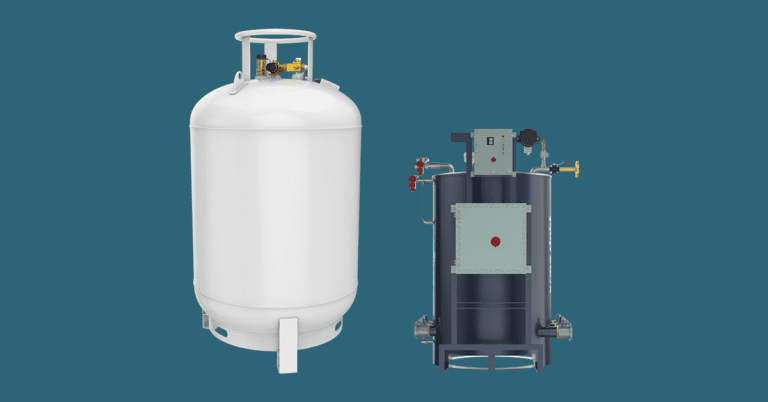

For more demanding applications, adding a vaporiser to ‘artificially’ increase vaporisation is the solution.

Vaporisers receive large volumes of LPG liquid and transform it to vaporised gas, at a steady rate and pressure from hundreds of kgs per hour to thousands of kgs per hour. The amount of heat transferred into the LPG controls the vaporisation rate, and the right vaporiser delivers a constant supply of vaporised gas as needed.

Below, we’ll help you understand the types of vaporisers available.

Water Bath Vaporizers:

Water bath vaporiser uses a water-based heat transfer medium for the heat source, and a heat exchanger for the LPG, propane, or butane liquid is immersed in facilitating heat transfer.

A water bath vaporiser uses an insulated “Bath” or enclosure that contains a coil type of heat exchanger through which Liquid LPG flow is directed. The bath is filled with a heat transfer solution heated by an electrical heater assembly at one end of the unit. Liquid LPG enters the coil as a liquid and absorbs heat from the “bath” enclosure around the coil.

As the LPG picks up the heat, it is transformed from a liquid to a vapour. The rate in this occurs is based on the flow rate of the LPG entering the bath and the amount of heat being introduced. A flameproof electronic control panel controls these functions. Safety features keep the system functioning correctly, and the control panel monitors both input and output pressures and temperatures.

Heater-less Vaporisers:

The heater less LPG vaporiser does not use any external electrical power vaporiser supply heat. This vaporiser works on the thermodynamic properties of volatile liquids. The liquid LPG is flashed by throttling the flow through a pressure reducing valve, and the consequent drop of pressure causes chilling. Ambient water provides heat to this chilled liquid LPG for vaporisation, in the heat exchanger. Because of the inherent design features heater less vapouriser function satisfactorily at ambient temperatures as low as 4° C.

The complete process uses no significant electric power source. The electric power is used to run the water pump, pumping ambient temperature water to the heater less LPG vaporiser. It draws this water from a large storage tank where the ambient temperature water flows to the heat exchanger and interacts with the chilled LPG. The storage tank’s capacity is designed so that the temperature drop in the storage tank is negligible.

Steam/Hot water Vaporiser:

This type of vaporiser uses on-site steam or hot water as the heat source for vaporising liquid LPG. A large facility that uses steam for its processes will typically have excess steam readily available.

By utilising either steam from a dedicated boiler or saturated process steam or hot water, the vaporiser units deliver efficient heat transfer and precise temperature control. By delivering consistent pressure and combustion, steam vaporisers ensure a continuous, dependable gas supply and uninterrupted operations.

Dry Electric Vaporiser:

These are typically small capacity vaporisers that use a heat exchanger heated by self-modulating electrical heaters.Energy transfers from the heat exchanger into the LPG as it passes through the tubes, causing the LPG to boil. These vaporisers require less maintenance when compared to other vaporiser types.

Selecting the right vaporiser for your application is essential to ensure the continuous, optimal performance of your equipment.